Modular In-plant Offices Built to Order

KABTech offers a broad range of modular in-plant office buildings which can be customized to fit any work facility.

Modular In-plant Offices have an unlimited number of uses and come in a variety of price ranges.

Request a quote for the latest up-to-date prices and project specifications.

See What KABTech Can Offer You!

We provide a variety of durable, attractive and affordable prefabricated office structures and modular multi-purpose buildings with unlimited flexibility.

We can also design and install custom modular in-plant offices or warehouse dividers to add additional room enclosures close to the production area.

Inplant modular designs can be enclosed with added soundproofing and climate control or can be open and used as a dividing system for production processes close to the assembly process.

We can also design and install two story offices, and offices on mezzanines that can be erected to add additional modular office space without taking up valuable warehouse floor space.

Versatile Prefab In-Plant Offices for Your Factory Upgrade

All modular in-plant office designs are attractive, versatile, and built to last. Inplant modular office space units are designed per your exact specifications and can be quickly shipped and installed without disrupting productivity.

To help facilitate a quick and easy installation, all of our inplant office enclosures are available in custom sizes so they can be adjusted and set in your facility accordingly. The versatile modular office walls and panel components are designed to be disassembled and reassembled as your industrial floor space needs change, thus saving time and money for in plant up-fitting.

Prefabricated office enclosures provide endless wall designs allowing for multiple door styles and placements including roll up doors. There are a variety of modular office window sizes and treatments that will allow you to place window as needed throughout the office enclosure.

Team Rooms, Break Rooms, Engineering and Conference Rooms

Modular Office Systems Save Time and Money

Modular office systems can be installed with minimal impact on production and provide significant cost and time savings compared to conventional construction. These prefabricated rooms bring a safe environment closer to the production area.

Pre-Assembled For Fast Installation

Many office designs can be pre-assembled at the factory and shipped directly to you. Customize your office system in a variety of ways by choosing the size, surface treatment, HVAC system, roof, windows, doors, electrical system, and more.

For more information on creating a modular team room, or to request a quote, please contact KABTech today. Our goal is to provide the best in quality, value, and service for our clients with advanced, cost-effective solutions for all of your workspace needs.

Removable Walls: Versatile Alternative to Conventional Construction

Our modular removable walls, ceiling panels, doors and modular glass windows offer long lasting resourcefulness which cannot be matched by any conventional construction. These removable wall structures can be reconfigured to your changing floor plan and can grow and expand easily with your industry, thus saving your time and money while ensuring a solution that can quickly adapt to your changing needs. Additional panels can be added at any time for additional office space without wasting any of the original structure.

In-Plant Modular Office Designs

Modular in plant offices are installed in a fraction of the time and without the dust and clutter compared to conventional building construction (beams and plywood are only required for load bearing roofs). This saves you money by minimizing production downtime and providing the flexibility to move or rearrange the buildings in the future.

Modular Construction Office Designs

KABTech is known for supplying unlimited resources and quality modular office products

Compared to conventional construction buildings, modular built offices offer a variety of benefits including versatility. Modular offices are designed to be quickly assembled, but they can also be quickly un-assembled and relocated as your floor plan changes.

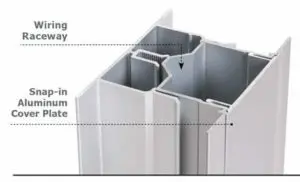

In-plant offices can be constructed from either steel or high strength extruded aluminum. This illustration shows the components that comprise a modular in-plant office system.

Modular Office Features

A 4 wall unit is shown, but 3, 2, and one wall configurations are also available. All of KABTech’s in-plant offices feature a non-progressive design, which means any office structure panel can be removed without having to disturb the adjacent panels.

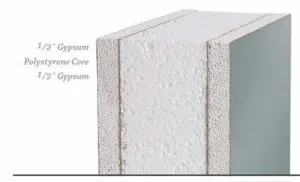

This not only makes our building easy to install initially, but it also makes it simpler to replace damaged components or to add new doors, windows, or walls. Panels are either 1.5” or 3” thick with hardboard, gypsum, FRP, steel, or other surface material on both sides.

The core material is expanded polystyrene, which meets FM and other insurance requirements for non-combustible and creates natural noise reduction wall panels.

Wiring posts are either painted steel or aluminum with a satin finish. Posts not only support the modular building system but act as wiring chases and have snap on steel or aluminum cover plates which provide easy access to electrical wiring for maintenance or future expansion projects.

Modular In-Plant Office Product Features

KABTech in-plant office enclosures can be custom configured with a variety of different textures, surfaces, and colors to fit any work environment.

You can select everything from load bearing capabilities and thermal insulation values to design features such as windows, doors, noise control options, and more.

The best feature of our modular in-plant offices is that they are relocatable, and can be quickly expanded or reused to provide long term versatility whenever a new situation arises.

KABTech Custom In-Plant Office Features Include:

In-plant office vinyl panels come in three standard colors which include white, gray, and beige. To help match your work facility, we have custom colors available with painted gypsum or steel.

In-plant office doors and windows can also be equipped with a variety of features which include: high-speed swing doors, sliding doors, and tinted or acrylic glass. For added security, we offer bullet and blast resistant frames, along with the ability to fully integrate with security cameras, access control doors and more.

Office Wall Stud Construction and Use of Materials

Office Panels That Fit Your Design Scheme

Vinyl covered hardboard is our most economical wall panel solution. The vinyl surface is durable, easy to clean, and is available in white, gray, or beige. 1-3/4″ panel is R-7 / STC 24; 3″ Panel is R-13 / STC 24

Gypsum

Our custom in plant structures offers a choice of painted or vinyl covered gypsum that is non-combustible and has added sound attenuation compared to the hardboard material. Gypsum is UL rated Class 1 non-combustible.

Gypsum wall material will meet building codes if your project requires a building permit. The vinyl covered gypsum is available in white, gray, or beige while the painted gypsum is available in virtually any color.

Steel Panels

Our painted 24 gauge steel modular panels add durability over the vinyl options. Steel panels can be painted any color and are ideal for matching existing buildings or equipment. Steel panels can also be laminated to our gypsum panels or directly onto the foam core.

Other choices of wall panel construction include:

Choices of Durable Office Wall Panel Coatings and Treatments

Wall surface options can include FRP (fiberglass reinforced plastic), which is ideal for restrooms or food production facilities. FRP is our maintenance free solution which is durable and waterproof to handle all kinds of environments and conditions.

Alternatively, our hardie-backer cement board material is used on all of our outdoor modular office buildings and is extremely durable and weather resistant making it perfect for outdoor office space projects.

What is the Ordering Process?

Your order process begins with clicking on request a quote. Simply give us,

- The name of your company and location

- A quick description of your plant’s modification needs

- Your name and personal contact information

We will route your information to a KABTech executive that will contact you to discuss the details of your project. They will be able to answer any questions and concerns you may have about the project and offer suggestions for fast shipping and installation. You will find that KABTech can show you ways to save money and select the optimum equipment for your requirements.

With modular office construction, any building inspections that are required can be done at any point of the installation process.

When ordering custom modular office, you will receive detailed drawings for your review and approval. When we receive your approval, we will begin the manufacturing process which is typically between four and six weeks. For most standard office orders you can plan to receive your order within approximately five to seven weeks from the time your order is placed. This will vary depending on order details, availability of custom treatments and shipping availability.

For more information see shipping details and more ->>>

The Perfect Solution for Enclosing New or Existing Equipment

In plant modular offices are the ideal solution for enclosing new or existing equipment without disrupting the original mounting position or disassembling.

It also gives you the ability to install the office and install equipment through the removable wall panels before completion.

The wall studs include wire tracking which provides electrical access at any location within the enclosure. The wall material choices provide durability and safety. The insulated roof paneling can also be fitted to provide extra protection of interior space with interlocking metal panels or the optional materials of your choice.

These modular enclosures are the perfect way to control room temperature, humidity, smoke, or production fumes, dust and noise and can be designed to be light eliminating for light sensitive processes.

Two-Story In-Plant Office or Mezzanine Office Will Double Your Available Floor Space

If available floor space is a challenge, then the best solution is building up.

Adding a second level to your modular office will enable you to maximize your available space. We design our two story modular offices to your meet or exceed your seismic zone and OSHA requirements.

Two Story Modular Office Systems

Another benefit of the second tier is the ability to have an excellent view of the facility. Two story modular offices can also provide multiple uses for the same footprint.

KABTech can also design raised industrial platforms that can be incorporated with a modular office on a portion of the work platform. Raised industrial platforms and mezzanines can take any form, shape or size you require. It can also be designed for in-plant or outside locations depending on the way you need to use the structural work platform.

Lower office levels can be utilized for break rooms, maintenance shops, training rooms or whatever quick employee access requires. While the upper level can be supervisor office space, conference rooms or management workspace. This allows you to pack multiple functions into half the available facility floor space.

Our versatile prefabricated two-story modular offices are easy to assemble and disassemble if the facility layout changes. For large offices, we can utilize our mezzanine system to create larger structures with maximum usable office floor space. This allows you to pack multiple functions into half the available facility floor space.

KABTech’s two story in plant offices include:

In-Plant Mezzanine Office Modular Systems

Our offices are completely prefabricated and easy to assemble and disassemble as your layout needs change. These modular mezzanine offices can also be built above existing offices or equipment. If floor space is already taken, we can design a clear span mezzanine that will allow you utilize your available vertical space. The mezzanine office can be used for applications other than just office space. These uses may be a conference room, quality lab, break room, training room, or other similar areas.

Options include:

In-Plant Offices and Mezzanine Safety Barriers.

Forklift safety barriers, safety bollards, and column guard protection can be added to your heavy traffic areas to prevent property damage and injury to employees from heavy machinery. KABTech’s professional staff is ready to assist you with designing, choosing the correct materials and constructing any in plant modifications your company needs from rubber floor covering to two-story in-plant offices. Call us today so we can help you get your project started.