Project Overview

An automotive parts manufacturer was looking to create office space for the production supervisor and maintenance manager of their facility. The warehouse location was a large open space with high ceilings, and the warehouse floor contained various equipment, manufacturing machinery, and assembly parts and materials. Overall there were four primary goals for this project:

- Provide an office space on the production floor.

- Increase the usable square footage of the designated area.

- Provide two secure storage areas.

- Allow access along the perimeter of the building for maintenance purposes.

The industrial interior products installed during the project were wire mesh partitions, a modular in-plant office, and a warehouse mezzanine.

Project Installation

The automotive parts manufacturer needed an office building to overlook the manufacturing floor; however, they did not want to sacrifice their valuable warehousing area. Additionally, our customer also wanted to create a secure storage area for spare parts and inventory. To solve both of these problems, KABTech installed a mezzanine which took advantage of the high ceilings and available vertical space.

The structural mezzanine was built out from the wall so the customer could access the piping and electrical systems with a scissor lift if needed. The mezzanine consisted of C-channel structural members and 9ea columns and was rated at 125psf. To provide safety for the top level of the building, KABTech installed a safety handrail which featured a sliding gate so the customer could use a forklift to place and review material on the mezzanine platform. The top layer of decking for the mezzanine floor was made from sturdy oriented strand board.

After the mezzanine had been constructed, KABTech secured the area underneath it with wire mesh partitions. This was accomplished by running the wire partitions from the existing concrete wall to two corners of the modular in-plant office under the mezzanine. A sliding gate was then installed in the wire partitions to provide secure access to the stored equipment. The gate has a keyed lock to prevent against theft and damages.

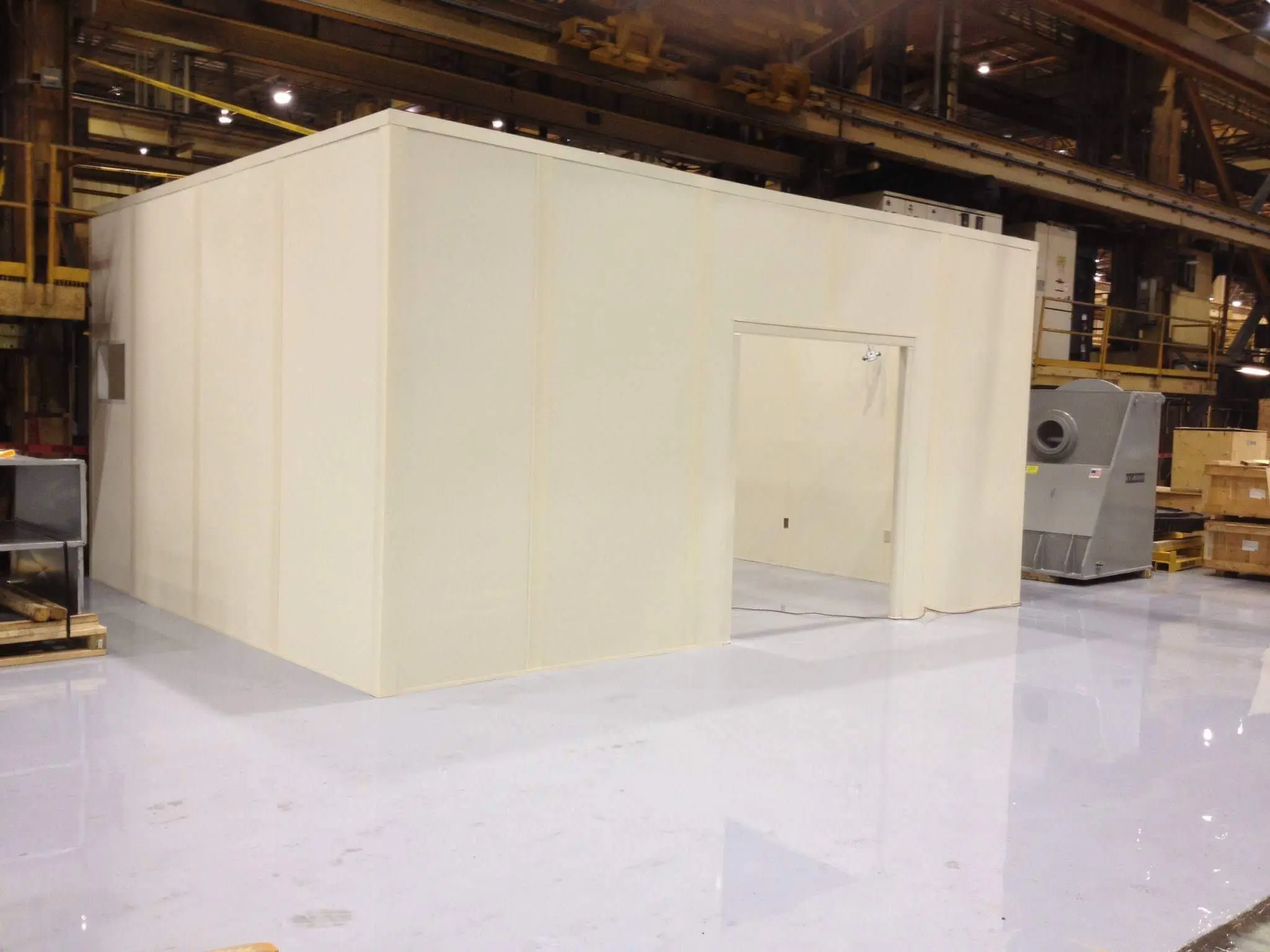

The modular in-plant office was built between the legs of the mezzanine. This allowed the mezzanine structure to be used to support the acoustic ceiling and electrical wiring. A Thru-Wall HVAC unit was installed to provide temperature control for office space, along with a key locking door and five laminated glass windows. KABTech also used modular wiring to speed up the construction process of the modular in-plant office.

End Result

In the end, the automotive parts manufacturer was more than thrilled with their new modular industrial building. The installation went smoothly and without incident, and the plant supervisor now has a private office without having to sacrifice any space on the floor.

Want to learn more? Contact us today to find out how KABTech can develop, build, and execute the design of your next in-plant office or structural mezzanine project. With over twenty years of experience, our team provides the best in quality, value, and service.

continue reading