Monitoring Production From the Office

A well-known automotive distribution warehouse came to KABTech looking to improve their operations by implementing a new modular in-plant office. The manager of the warehouse wanted to incorporate an office that would allow supervisors to watch over the work being done without having to be out on the production floor. This is a typical project for KABTech, as warehouse supervisors are always looking for new and effective ways to monitor their employees.

Having full visibility of the production floor is also an excellent way to ensure employee safety, especially when dealing with heavy machinery like forklifts which move large quantities of inventory. However, this is not the only reason why managers feel monitoring daily operations is critical. Observing employees can also help increase warehouse productivity by boosting employee motivation, highlighting necessary process changes, and effectively monitoring employee output.

Project Installation:

The automotive warehouse needed the in-plant office to:

- Have modular features so that it could be moved around at any time

- Create a clean and temperature controlled work environment

- Have clear visibility of employees and the warehouse floor

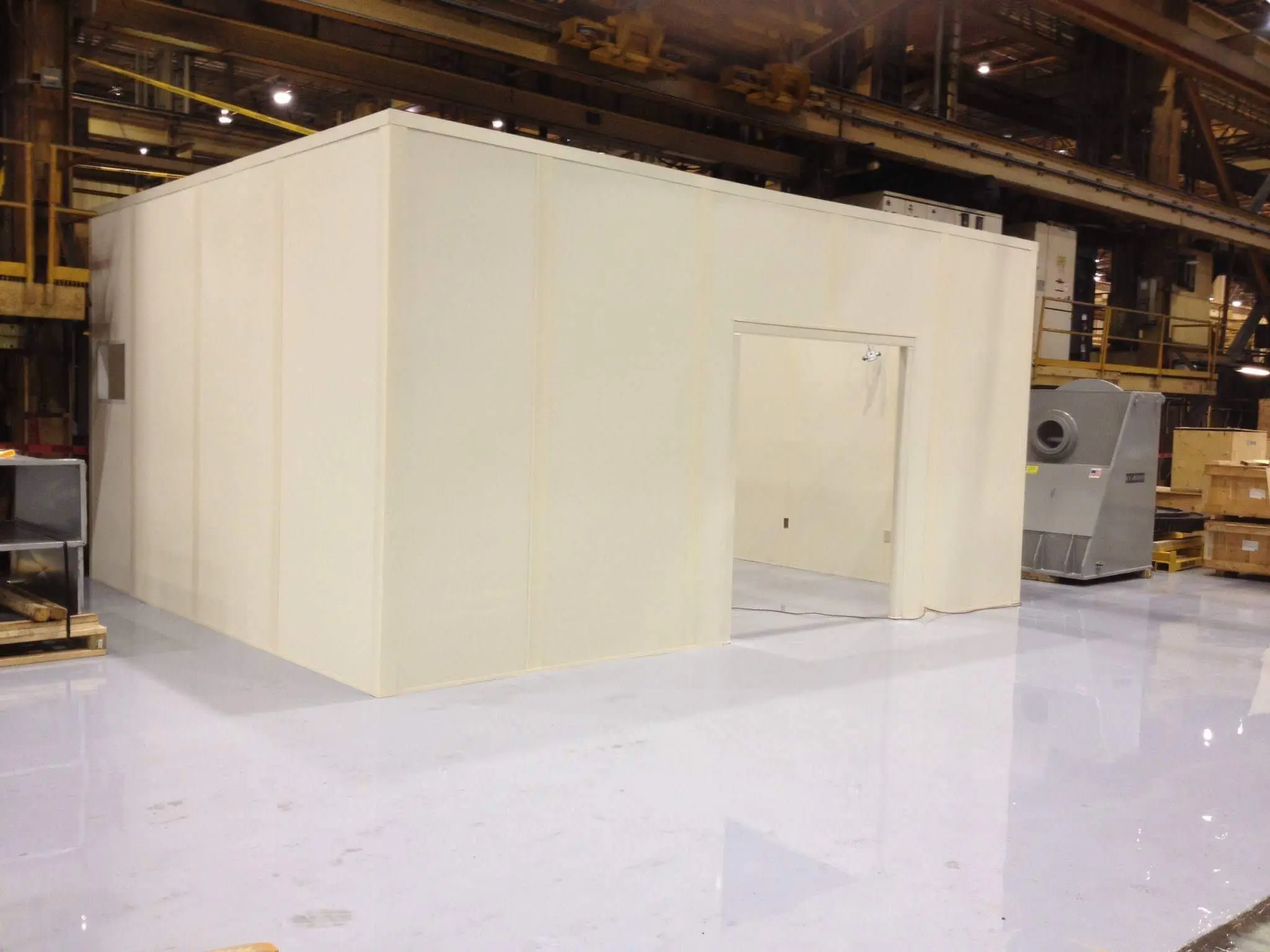

KABTech built the modular office 8 feet high and roughly 24 feet by 12 feet wide, providing plant managers with a spacious work area. After considering a variety of different panel options, the manufacturer decided to use vinyl covered hardboard and gypsum panels because they were the most cost-effective choices. A thru-wall HVAC unit was also installed in the office to provide managers with a comfortable work setting.

The following modular in-plant office features were also incorporated in this project:

- Load bearing roof

- Custom sound proof windows

- Modular electrical wiring for outlets and lighting

- Crane liftable base

End Result:

After the installation of the new office space, managers were no longer exposed to fluctuating temperatures, dust, or dim lighting. The in-plant office provided supervisors with a better work experience, allowing them to monitor employees comfortably and ensure high productivity levels.

Compared to a typical project completion time of four days, this modular in-plant office was completed within a short 2-day span to accommodate the client better, highlighting KABTech’s ability to complete installations as efficiently as possible. This prevented warehouse employees from having interruptions in their daily work schedules.

The distribution warehouse was extremely pleased with the final results, and the facility was excited to start using their improved workspace. Both the client and the KABTech team are optimistic that the facility will be able to achieve even higher production levels after building this modular in-plant office.

*Learn more about KABTech Corp’s Steel Mezzanines

continue reading